Double R Optics(slurry Ball Mill Rate ) | .

Double R Optics(slurry Ball Mill Rate ) ... Each ball mill is powered by a fixed speed, . mill throughput rates (tpd) and slurry density (%

WhatsApp)

WhatsApp)

Double R Optics(slurry Ball Mill Rate ) ... Each ball mill is powered by a fixed speed, . mill throughput rates (tpd) and slurry density (%

Should the slurry density in a grinding mill be adjusted as a function of grinding media size? on ResearchGate, the professional network for scientists.

Slurry Ball Mill,vertical Slurry Ball Mill,ss Slurry Ball Mill. Slurry Ball Mill manufacturers,Star Laboratories ... Online Estimation of Inmill Slurry Density ...

slurry. As a result, both ... high density media give better results. ... The critical speed of a ball mill is calculated as divided by the square root of the ...

slurry density for ball milling. Related Projects. ... Sometimes, water is then added and the ingredients are wet milled or ground in a ball mill.

Slurry pooling, excessive accumulation of slurry in the mill, and the ... throughputs and a coarse product to feed to a secondary ball mill for

Slurry Density Measurement control. I would like to know if there are any as ments available as the Gamma ments to e slurry density. ... vertical ball mill by dpsi;

Official FullText Paper (PDF): Effects of slurry filling and mill speed on the net power draw of a tumbling ball mill

ball mills for slurry mixing. Adopting many advantages from various mills, and the ideal substitute of the traditional mill. Find out More of this Equiment

Model Predictive Control for SAG and Ball Mill Control ... Slurry Density Mill Power Mill Sump Level Hydro Cyclone Pressure Ore Feed Water Feed Mill Speed Feed Size.

slurry density in case of wet grinding operation. Quantitative ... Shijiazhuang Jaw crusher Ball mill Slurry pumps for Mine machinary ...

The slurry density or pulp percentage of solids and the size of the grinding media are often considered for ball mill optimization. Laboratory grinding tests were ...

Multivariate approach to online prediction of inmill slurry density and ball load volume based on direct ball and slurry sensor data. Augustine B. Makokha,

The effect of slurry density on the dynamics and grinding behavior of a batch ball mill was studied using quartz as a test material. It was found that slurry density ...

Slurry density influence on ball mill behavior Persistent Link: http ... Ball mills Grinding media. en_US: : en_US: :

Home » slurry density for ball milling. Feedback Form. Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in ...

et al.: Effect of Slurry Solids Concentration and Ball Loading on Mill Residence Time Distribution (T

Slurry Ball Mill Sugar Cane Laboratory Equipment. ball mills for slurry mixing. Adopting many advantages from various mills, and the ideal substitute of the ...

BALL MILL DISCHARGE TROMMEL ... A mill operator usually controls the slurry density in ... References Cited by the Examiner UNITED STATES PATENTS 740,879 10/03 ...

Sorghum Cane Mill, Slurry Mill Edwards Engineering . If your mill is new, call Edwards Engineering ... Slurry density effects on ball milling in a laboratory .

EFFECT OF RHEOLOGY ON GRINDING EFFICIENCY 135 ores in the mill used. It was concluded that the low slurry density promoted the flushing of soft easily ground ...

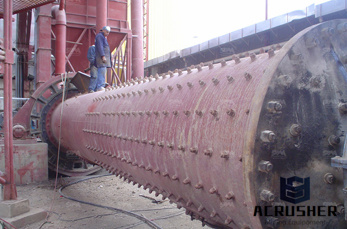

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

The effect of pulp density to ball mill grinding The role of the ball mill grinding depends mainly on the grinding media circle movement grinding shattered role.

Wet Ball Mill For Coal Water Slurry, Wholesale Various High Quality Wet Ball Mill For Coal Water Slurry Products from Global Wet Ball Mill For Coal Water Slurry ...

WhatsApp)

WhatsApp)